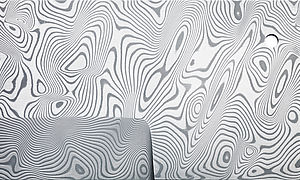

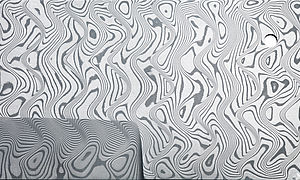

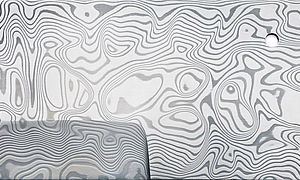

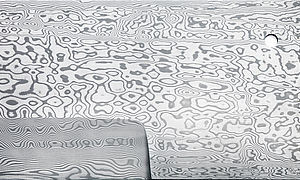

DSC inox is a stainless, martensitic damascus steel and is characterised by producing a good cutting edge, a very fine structure and high working hardness. Moreover, this steel composite reacts with very low distortion during heat treatment.

GARANTEED MANUFACTURING RELIABILITY

The steel layers bonded during the composite welding process do not open up during any further hot forming or burr removal. Thus manufacturing reliability can be guaranteed. Due to the favourable blade steel properties and reliability that are important in production and processing, this damascus steel is especially well suited for use in further industrial production.

Processing

You will find detailed information on working and processing as well as heat treatment and the etching process here.

APPLICATIONS

Regardless of where our DSC inox is used, in the kitchen, the pocket or in the field the product is perfectly suited as a result of it’s fine grain and stainless properties. Fault free layer welds are the basis for the superb quality of this steel.

Your unique requirements and ideas come first and are our guideline - we are ready to produce according to your special wishes. The combination of steel used can be altered to your specifics, for example. Feel free to contact us and discuss your specially produced DSC inox.

QualitY

We have been producing custom Damascus steel since 1991 and you will profit from our experience. DSC inox combines the know-how and experience of over 25 years.

Our patented DSC Superclean process gives us 120 layers, with other layer and component combinations possible per request. Our unique process is exemplified by the extreme cleanness and fine grain without weld faults.

CHARACTERISTICS

- SuperClean-layer welds

- Corrosion resistant

- Very fine grain

- Reliable production process

- Multiple options, patterns and dimensions

- High edge holding

- High hardening possible (up to 61 HRC)

- Fit for food contact

- Uncritical misforming after heat treatment